Federal government sets and enforces strict auto glass safety standards for driver/passenger protection. These cover materials, production, installation, and post-installation inspections. Adhering to these standards is vital for automotive manufacturers and repair services, enhancing customer satisfaction and safer roads. Rigorous manufacturing, installation processes, and quality control ensure structural integrity and impact resistance. Regular inspections and training strengthen safety of auto glass replacement/repair. Testing includes impact resistance, penetration, and temperature endurance assessments. Strict manufacturing processes and material inspections meet federal criteria for quality assurance. Proper maintenance and timely repairs prevent safety hazards and enhance vehicle integrity.

“In ensuring driver and passenger safety, understanding federal auto glass safety standards is paramount. This article delves into the critical components of these regulations, shedding light on the manufacturing and installation processes that shape modern vehicle safety. From rigorous testing procedures to quality assurance measures, we explore how these elements protect against potential hazards. By comprehending these standards, consumers can rest assured that their vehicles meet stringent safety benchmarks, fostering peace of mind on the road.”

- Understanding Federal Regulations for Auto Glass Safety

- Key Components: Standards for Manufacturing and Installation

- Ensuring Passenger Protection: Testing and Quality Assurance Measures

Understanding Federal Regulations for Auto Glass Safety

The federal government plays a vital role in ensuring auto glass safety standards across all vehicles. Understanding and adhering to these regulations is crucial for both automotive manufacturers and collision repair services. These standards govern everything from the materials used in production to the installation process, with the ultimate goal of protecting drivers and passengers in the event of an accident. Compliance ensures that auto glass not only resists impact but also performs well under extreme conditions, minimizing potential hazards.

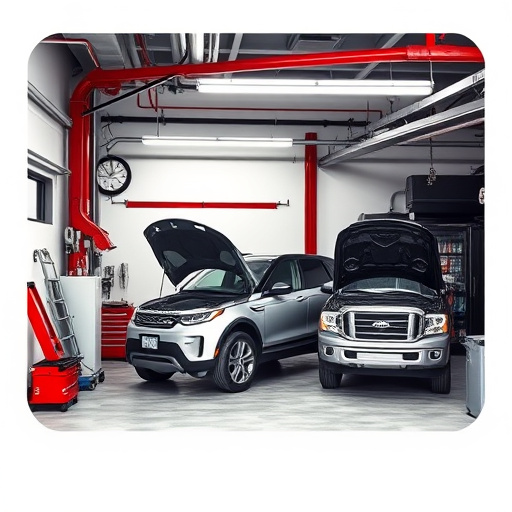

For businesses specializing in automotive repair services or frame straightening, knowledge of these standards is essential. It dictates the types of glass permitted, installation techniques, and even post-installation inspections. By keeping up with evolving regulations, these professionals can offer high-quality, safe repairs. This not only enhances customer satisfaction but also contributes to the overall safety of the nation’s roads, making it a critical aspect of collision repair practices.

Key Components: Standards for Manufacturing and Installation

The key components of federal auto glass safety standards revolve around rigorous manufacturing and installation processes. These standards ensure that auto glass used in vehicles meets stringent quality control measures, guaranteeing its structural integrity and impact resistance. Manufacturers must adhere to specific guidelines for materials, design, and production techniques, ensuring the glass is both safe and reliable.

During installation, precision and adherence to guidelines are paramount. Proper sealing, alignment, and fastening techniques are essential to prevent glass detachment or shattering under stress. Regular inspections and training for installers further bolster the overall safety of auto glass replacement and repair processes, whether for car restoration or damage repair projects.

Ensuring Passenger Protection: Testing and Quality Assurance Measures

In ensuring passenger protection, auto glass safety standards demand rigorous testing and quality assurance measures. These standards are designed to prevent injuries and fatalities resulting from shattered or improperly installed vehicle glass during accidents. Testing protocols include impact resistance, penetration tests, and temperature endurance assessments, all aimed at validating the structural integrity of auto glass under various conditions. Quality assurance involves stringent manufacturing processes and material inspections to guarantee that only high-quality components meet federal safety criteria.

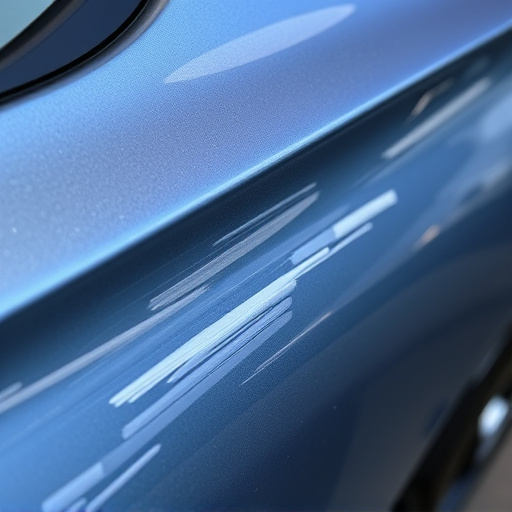

Beyond adhering to these standards, proper maintenance of vehicle windows, windshields, and side mirrors is crucial for optimal safety. Regular checks for cracks, chips, or signs of wear can prevent minor issues from escalating into significant safety hazards. Just as important are timely repairs, including bumper repair and car paint repair, which not only enhance the aesthetic appeal but also reinforce overall vehicle integrity, contributing to passenger security on the road.

Auto glass safety standards are paramount in ensuring passenger protection and preventing accidents. By understanding federal regulations, adhering to manufacturing and installation guidelines, and implementing rigorous testing procedures, the automotive industry can significantly enhance overall vehicle safety. These key elements collectively contribute to a robust framework for maintaining clear visibility and mitigating risks on the road.